Hangcheng is a specialized enterprise that integrates casting machinery processing and mold design and manufacturing.

Hangcheng is a specialized enterprise that integrates casting machinery processing and mold design and manufacturing.

if you are looking for a quality investment casting manufacturer then look no further because we have you covered.

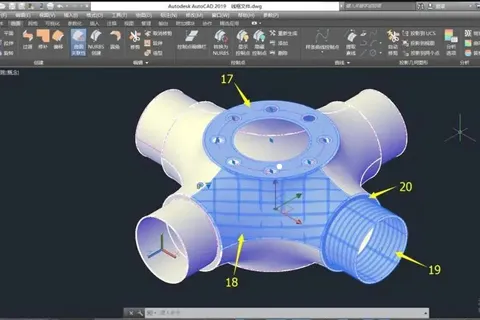

During the initial consultation and review, HangCheng Castings Engineers and Production Manager will determine the best casting option based on the unique parameters of a customer’s project.

General criteria used to select the optimal casting method are: material, size of the product, quantity, dimensional tolerances, desired finish, tooling and production costs, lead times, design intricacy, and post casting processes.

Our team at HangCheng Castings takes all factors into consideration to establish the best production method for each project or part. Each decision is based on an overall analysis taking all factors into consideration.

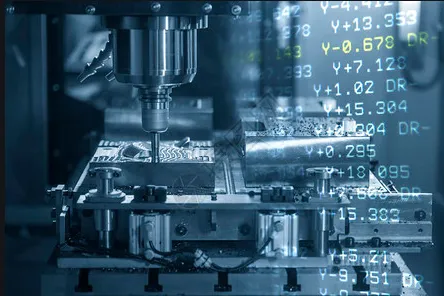

Do you have any special requirements for the testing program of the parts, or do you want us to implement a special technology to post-process your original parts? We are driven by your needs – that’s why we have been searching for new solutions to customize our services more specifically according to your wishes. A recent example: abrasive flow machining, a special post-processing method used to improve surface quality, is only adopted by a very few foundries. Together with us, this is part of our standard service scope – meeting the requirements of many customers.

You place maximum demands on the casting materials from which we produce your part. This is why we guarantee absolute analytical fidelity during the melting process and apply several test methods.

We understand that high quality, low cost and short lead times are very important to our customers. To ensure we can provide these elements, we employ a lean manufacturing approach to each operation required throughout the casting process in our investment casting foundry. Doing so eliminates waste, lowers cost and increases quality. We incorporate multiple steps into single manufacturing processes and cross train technicians. For example: wax injection, mold building and first dipping are all done by the same operator which speeds up the process and minimizes hand offs.

The enterprise has very complete casting production equipment, advanced physical and chemical analysis, and testing equipment, which can meet the requirements of customers at different levels. At the same time, the enterprise also continues to introduce Vanguard International Semiconductor Corporation advanced technology and a large number of professional technical personnel, expand advanced production and testing equipment, and the enterprise’s technical force is becoming increasingly strong.