Processing with Supplied Drawings

CASTING AND SUPPLY CHAIN SOLUTIONS,THAT ADD TO YOUR BOTTOM LINE.

Wuyi Hangcheng Machinery Co., Ltd. is located in Tongqin Industrial Zone, Wuyi. Is a collection of mechanical design, casting, machining, surface treatment in one of the new generation of machinery company. The company has modern casting production line, electronic melting furnace, advanced CNC processing equipment, perfect quality testing means and instruments, with complex casting and precision machining experience and technology development capabilities.

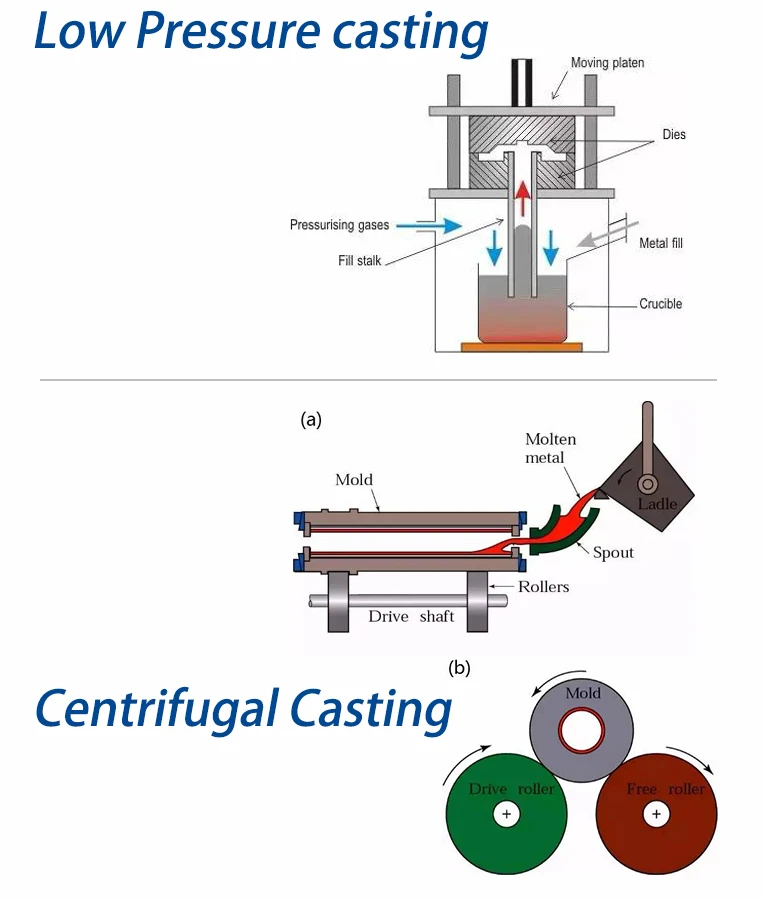

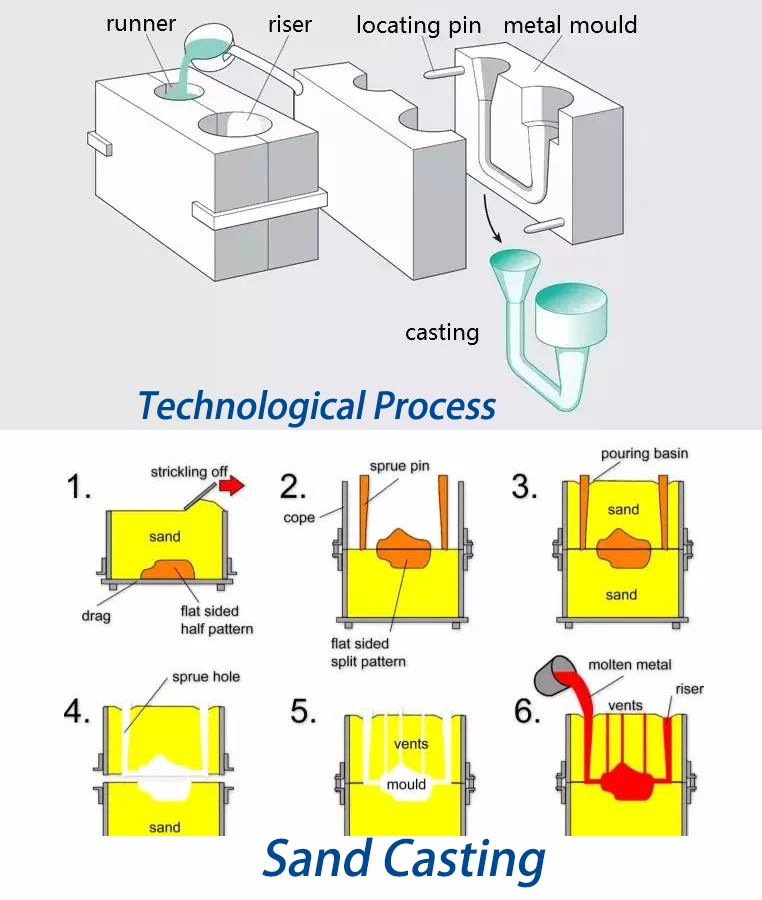

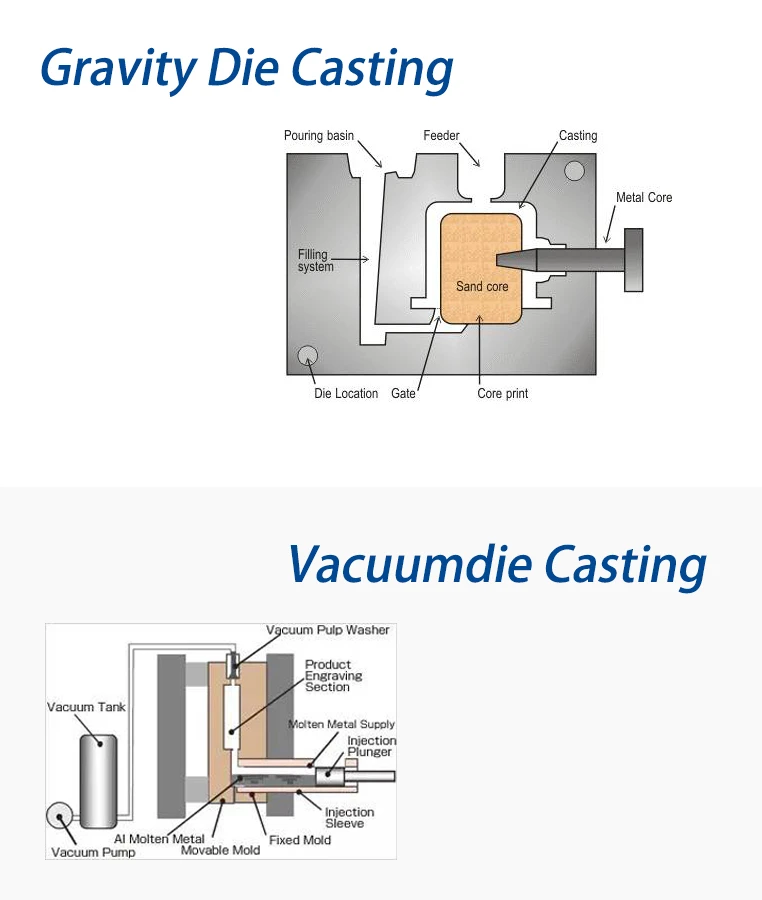

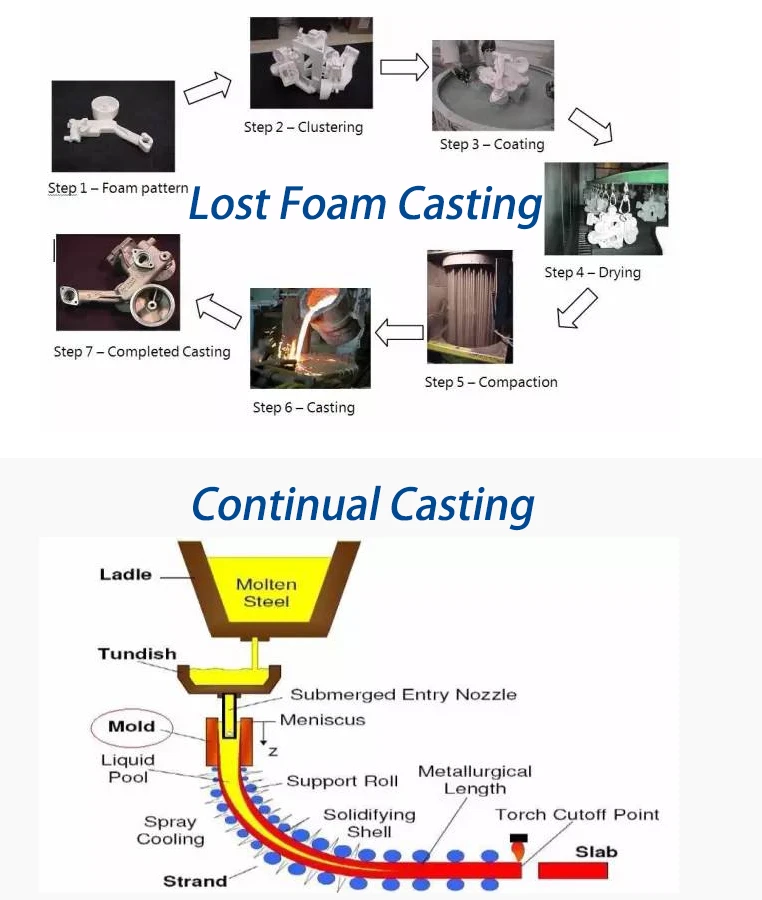

The production method of pouring liquid metal into a mold cavity that is suitable for the shape and size of the part, and waiting for it to cool and solidify to obtain a blank or part, commonly known as metal liquid forming or casting.

Process flow: liquid metal → filling → solidification shrinkage → casting

1. It can produce parts with any complex shape, especially those with complex inner cavity shapes.

2. Strong adaptability, unrestricted alloy types, and almost unlimited casting size.

3. The material source is wide, the waste can be remelted, and the equipment investment is low.

4. High scrap rate, low surface quality, and poor labor conditions.